Music in wood

In the Schwarz harmonica factory in Molln, Upper Austria, several hundred instruments “see the light” of the music world every year. In the modern machine park, the heart of production is a precise 5-axis CNC machining center from Felder.

Music in wood

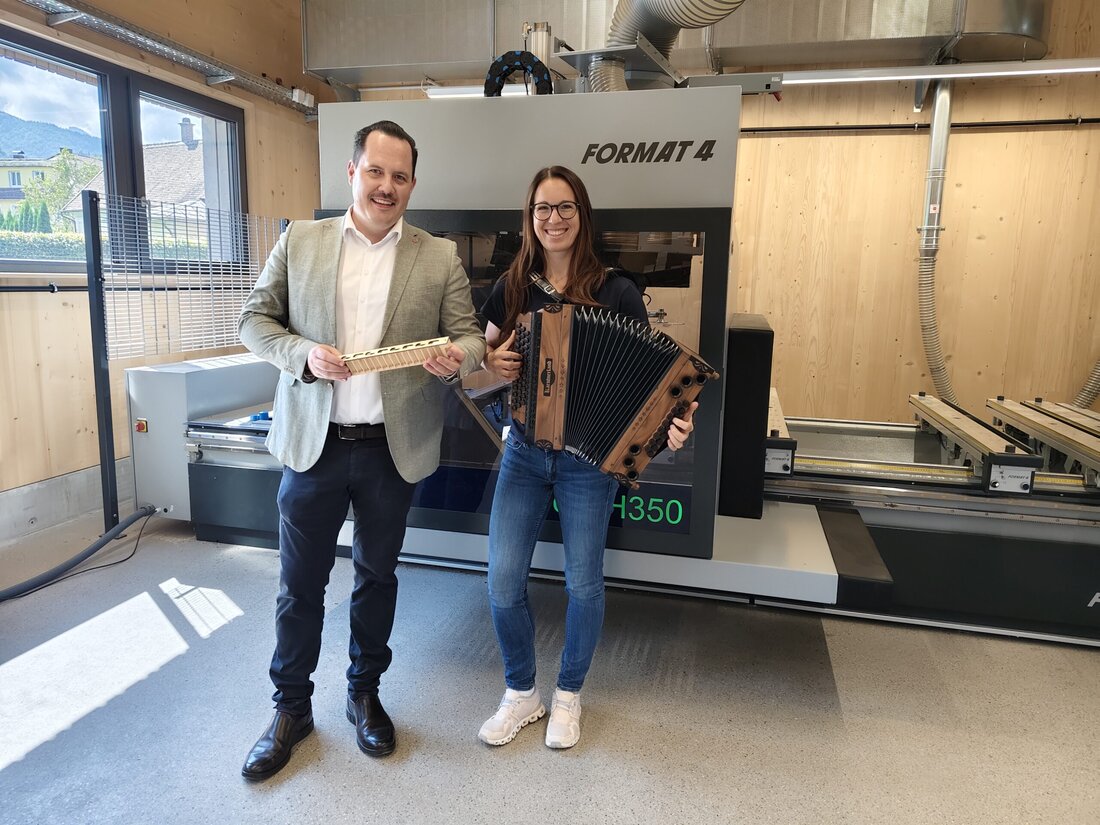

Lisa-Maria Schwarz welcomes the editorial team and immediately demonstrates her enjoyment of the instrument. She puts a harmonica around her neck, plays a few bars and explains to us the basics of the Styrian Knopferl harmonica.

But right from the start: it all started with a jew's harp in Molln, Upper Austria. The oldest musical instrument manufacturer in Austria has been located there since 1679 and today produces high-quality Styrian harmonicas. Jew's harps are still around, and up to 70,000 pieces are exported worldwide to over 40 countries every year.

Grandfather Karl Schwarz Senior recognized the great similarity between the vibrating spring of the Jew's harp and the reed of the Styrian harmonica. This marked the beginning of a new era in the company; the “Original Kärntnerland” harmonica was born. The name arose from the grandparents' connection to Carinthia. In 1980, the current managing director, Karl Schwarz Junior, joined the company, took over management in 1995 and, together with his wife Maria, expanded the family business into an internationally successful manufacturer of high-quality harmonica construction.

The two daughters were already enthusiastic about the Styrian harmonica as children and have been integrated into important company functions for several years: Lisa-Maria, a trained harmonica maker, heads production, Michaela studied business administration and is responsible for marketing and sales. This means that the two sisters complement each other ideally and cover both the craftsmanship and the commercial components of the business. Together they will continue to run the company in the 13th generation.

Sustainable new building with high-tech manufacturing

Over the decades, the company has continued to develop and wanted to be able to produce even more independently, flexibly and customer-oriented. "With our new building, we are keeping the greatest possible expertise in our own hands, securing existing and creating additional jobs and thus increasing regional added value. It was important to us that we create our unique competence center for the Styrian harmonica here," explains Lisa-Maria Schwarz. It was also very important that the supplier companies were in the immediate vicinity. This keeps transport routes short and efficient.

After two years of planning and around a year of construction, what is now, according to its own definition, the “most modern harmonica manufacturer in the world” was opened this April, which “attracted” more than 1,500 visitors to Molln over the five days of the in-house exhibition. The new production facility offers around 800 square meters of additional space for the production of the “Original Kärntnerland” harmonica. Sustainability was an important topic: “The entire building is constructed of solid wood, we heat and cool with geothermal energy and generate electricity with photovoltaics,” says Lisa-Maria Schwarz.

Out into the wide world...

The exclusive original Kärntnerland harmonicas inspire thousands of private players at home and abroad as well as many prominent musicians, including world champions. The harmonicas are optically and technically manufactured precisely to the individual ideas of a player. Schwarz: “The variety of high-quality materials, the attention to detail and our decades of experience make every instrument unique.”

A lot of work with 2,000 individual parts

Every year several hundred instruments leave the workshop in Molln. “We now manufacture and process almost all parts of the harmonicas in-house.” The new, spacious carpentry workshop now makes it possible to produce the “workpiece” – the original Kärntnerland harmonica – even more specifically according to customer requirements. This means that harmonica players can freely choose the wood and equipment variant. Each solid wood case is carefully crafted from various local tonewoods. For all components of a harmonica, Schwarz uses high-quality, predominantly regional wood species such as maple, oak, alder, ash, spruce, larch, nut, cedar and pine. The wood is stored at a comfortable temperature in a side room in the workshop. A Styrian harmonica consists of up to 2,000 individual parts, some of which are very complex, and requires up to 200 hours of work, depending on the model.

Modern technology meets traditional craftsmanship

In order to be able to produce much more efficiently here, Felder has supplied a machine park that is technologically up-to-date. These include the 5-axis CNC machining center profit H350R (Format4), which produces individual harmonica parts with an accuracy of hundredths of a millimeter, as the heart of the workshop. For example, the sound post (where the sound is generated by airflow) which is machined with special milling tools from Sperl Werkzeugtechnik. Furthermore, a circular saw, two planing machines for dressing and thicknessing, a table milling machine, a circular saw, a wide belt and an edge grinding machine as well as a grinding table and work tables work in the very tidy workshop. “With the new, expanded workshop and the great Felder machinery, we are ideally equipped to produce harmonica in the future with a quality and variety that has never been seen before,” says Lisa-Maria Schwarz happily. But despite the powerful machine support, the production of a complete original Carinthian harmonica currently remains around 80 percent fine, traditional handwork with dedication and precision. (gw)

The machine park

- Format4 5-Achs-CNC Bearbeitungszentrum H350R“

- Felder Kreissäge K700S

- Felder Abrichthobelmaschine A941 Silent Power

- Felder Dickenhobelmaschine D963 Silent Power

- Felder Tischfräse F700Z

- Felder Breitbandschleifmaschine FW850

- Felder Kantenschleifmaschine FS900K

- Felder Schleiftisch FST 160

- Felder Arbeitstisch FAT 300

At a glance

- Unternehmen: Schwarz Harmonikamanufaktur, 4591 Molln

- Mitarbeiter: 17

- Gründung: 1679

- Schwerpunkt: Musikinstrumentebau

- Maschinenpark: CNC-Maschinen

Suche

Suche